Starting a small mabati factory is a brilliant way to capitalize on Africa’s booming construction industry. Instead of tying up all your wealth in idle plots of land or rental apartments, why not take a different approach and venture into value-addition? This way, you end up meeting consumers’ immediate needs and in so doing you also create employment. And of course there are better financial returns in taking this route.

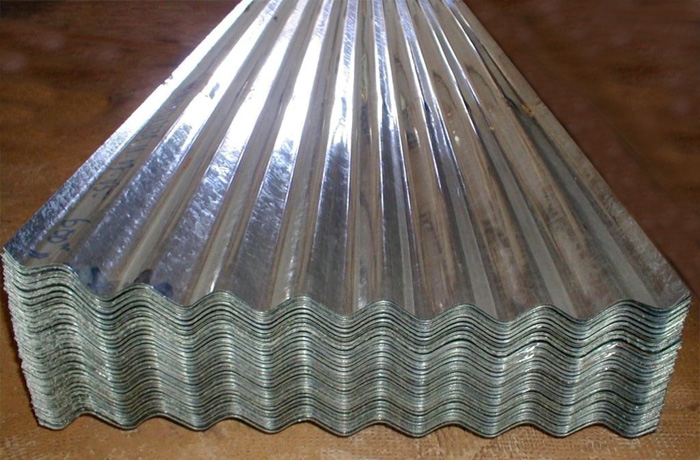

Mabati, or iron sheets in English, are a basic requirement for every construction project. Being a fast moving consumer good, you can hardly go wrong with this venture provided you invest in the right technology combined with creative marketing. There are very few local companies providing quality iron sheets, given that this industry has been dominated by foreign multinationals since time immemorial.

Getting Started

A mabati factory is typically made up of three things (1)Land (2)Machinery and (3)Labor.

Land

You can lease land in a fast growing area near a major highway. Think of places like Salgaa near Nakuru, Naivasha or even Sultan Hamud area along Mombasa road. You can buy or lease a minimum of 1/8 th acre plot where you will construct a warehouse-kind of structure (or you can rent a ready-made building).

Machinery

Invest in a roll forming machine. This can be obtained from countries like China, India or even Belgium. The cost may vary from one machine to another but typically you can acquire an average one for Ksh3million shillings. This is an all in one machine, with everything needed to form and cut mabatis ready for the market.

Besides the machine you will require a some Iron sheet coils. A coil can cost you anywhere between Ksh50,000 and Ksh100,000 depending on its length and gauge.

Tip: Since this is huge investment you might want to first travel abroad to build connections with suppliers. You can for instance travel for the annual Canton Fair which happens in China every year. There are some local companies which organize logistics for this and you only pay Ksh200,000 for a whole week’s visit.

Labor

You can start the factory with as few as 3 employees. You can handle the marketing/management/HR/CEO/accountant work yourself until your company is big enough to hire more guys. All you want to make sure is that you only hire honest individuals who can be entrusted with running the factory even while you are away.

Others

You need to register your company name (cost: Ksh3,000 approx) or register a limited company (cost: approx: Ksh30,000). You also need a KEBS license once you start making your products (cost: Ksh40,000 approx). Your county will also require you to pay a single business permit (cost: varies from one county to another).

The Business

To begin producing mabatis, you simply feed the iron sheet coil into the machine. You can program the machine to cut and shape the sheets according to your needs.

The size of the coil varies in terms of length and gauge. Generally, a 30 gauge unit with about 1000 metres of sheet would be a good bet to start with.

That means you can produce as much as 400 iron sheets per coil (with each sheet measuring 2.5 meters). Each meter of mabati goes for Ksh330 on average meaning you can make as much as Ksh268,000 per coil.

Related: Start making roofing tiles out of waste plastic, here’s a step-by-step guide

How Much To Invest

Ksh5 million would be adequate to set up a small facility, which can supply up to 100 orders per month.

How Much To Expect

This largely depends on your sales abilities. You can reach out to more customers by offering perks such as free countrywide delivery services. Sticking with the conservative figure of 100 customers per month then we can project an average revenue of Ksh4 million per month.

Challenges

*High startup cost

*Leasing premises in a strategic location may be expensive

*Finding skilled and competent workforce

*Most raw materials have to be imported

Final Word

Starting a small mabati factory offers you two extremes. On one extreme, there are numerous challenges to be overcome along the way especially when starting. On the other extreme, there is limitless potential once you start operating. It is upon you to decide whether you are ready for the rumble in the jungle or you just want to sit there and be a spectator.